Эта страница доступна также на Русский языке

Эта страница доступна также на Русский языке

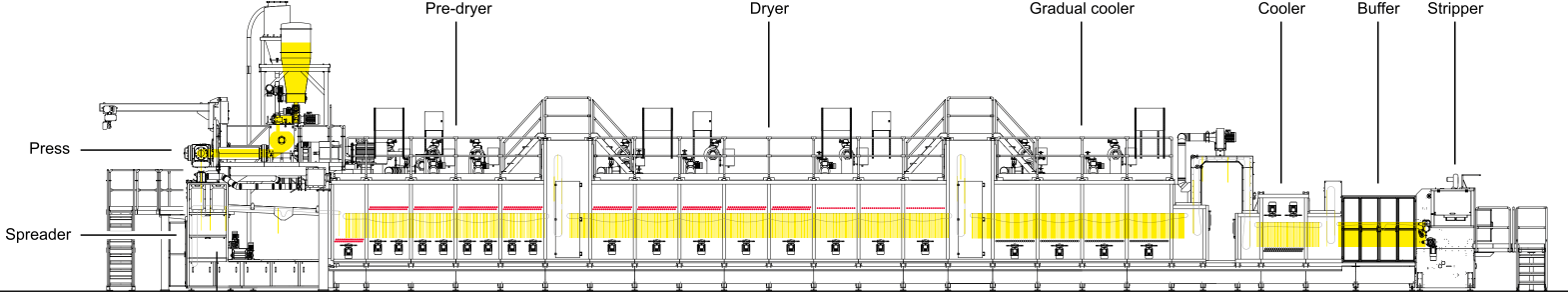

The most important features of this equipment are TURBOMIX technology and low-speed of extrusion, which is achieved thanks to the high-efficiency compression screws: these characteristics allow to obtain a very homogenous dough. The press can be fitted either with Total Vacuum System or traditional technology.

This equipment allows a homogeneous spreading of the Long-Cut Pasta on 2550 mm sticks. It is provided with an automatic system for fresh scraps recovery and a pneumatic conveying system to the press.

The surface of the Long-Cut Pasta is pre-dried, with a continuous hot air flow, to prepare the product for the subsequent drying phase.

Thanks to the MONOTIER technology, a succession of ventilation phases and off phases occurs with the maximum simplicity, completely controlled by automatic systems of thermohygroregulation.

The cooler, which features an heat exchanger entirely made of stainless steel, allows to lower the temperature of Long-Cut Pasta and make it suitable for storage and / or packaging.

With a storage capacity of approximately 30-35 minutes, the buffer makes it possible to store Long-Cut Pasta on sticks before the stripper, to compensate possible short shutdowns of the packaging system.

The stripper automatically removes the sticks and cuts the pasta to the length required for the next phase of packaging.

The Packaging System represents the last phase of the process.

The pasta obtained enters the Packaging machine and, according to its shape, is packed in the most suitable package, which will then reach the end consumers.

ARS (AXOR Remote Service) is the automation and supervision system completely developed by AXOR.

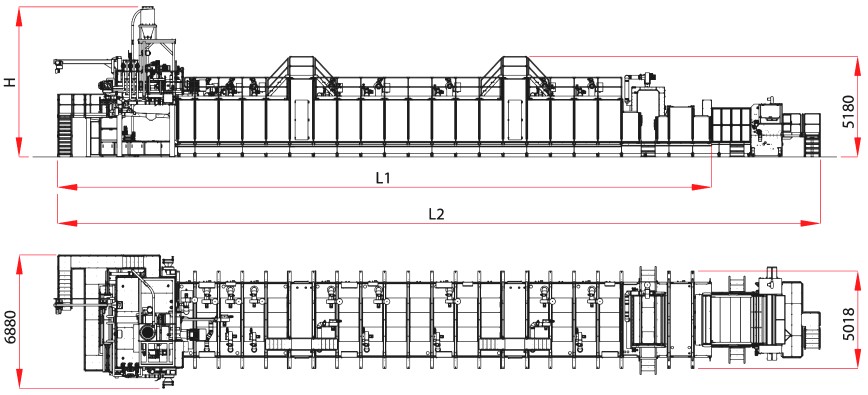

| Output capacity (Kg/h) | Press | Spreader | Line composition | H (mm) | L1 (mm) | L2 (mm) |

|---|---|---|---|---|---|---|

| 1000 | 1.210.L 2550 | ST.AX-1 | LPL-M + Buffer | 7700 | 33200 | 38700 |

| 1500 | 1.210.L 2550 | ST.AX-2 | LPL-M + Buffer | 7700 | 42800 | 49200 |